| Hello, welcome to the website of OSNAI! | hotline : 0769-81218861 13929235642 | INFORMATION | | | English | | | 設為首頁 | | | 加入收藏 |

| Hello, welcome to the website of OSNAI! | hotline : 0769-81218861 13929235642 | INFORMATION | | | English | | | 設為首頁 | | | 加入收藏 |

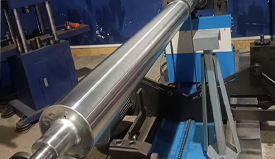

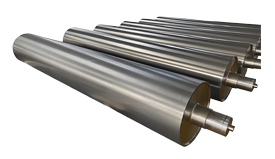

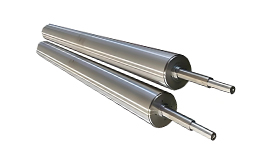

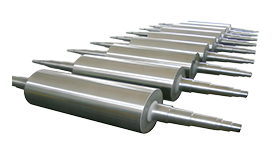

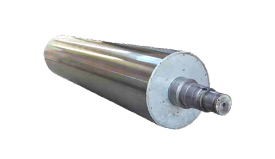

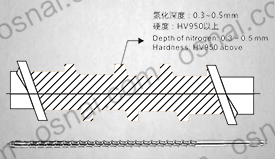

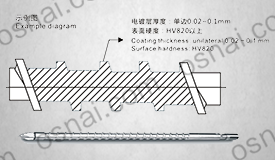

Stainless steel rollers have the following significant advantages in industrial applications due to their material properties and manufacturing processes: 1. Strong corrosion resistance Stainless steel (such as 304, 316) contains alloying elements such as chromium and nickel, which can form a dense chromium oxide protective film and effectively resist corrosive media such as water, acid, alkali, and salt, Suitable for humid, chemical, and marine environments, with a longer lifespan than carbon steel rollers. 2. Excellent hygiene performance The surface is smooth and pore free, not easy to breed bacteria, easy to clean and disinfect, and meets the hygiene standards of the food and pharmaceutical industry (such as FDA, GMP). Commonly used in food processing, packaging, and medical device production lines. 3. High temperature resistance and oxidation resistance Stainless steel can maintain stability at high temperatures (such as 304 can withstand 800 ℃, 310S can withstand over 1000 ° C), making it suitable for high-temperature processes such as baking and heat treatment. 4. High strength and wear resistance Hardness and wear resistance can be improved through heat treatment (such as quenching) or surface hardening (chrome plating, tungsten carbide spraying), which is suitable for high load rolling, rolling and other scenarios. Main application areas 1. Food and beverage processing Application: Conveyor belt rollers, pressure rollers, slitting rollers, sterilization equipment rollers, etc. Requirement: Food grade stainless steel (304/316), mirror polished surface, easy to clean. 2. Chemical and electroplating industries Application: Acid and alkali solution conveying roller, electroplating tank guide roller, anti-corrosion equipment roller. 3. Printing and packaging machinery Application: Coating roller, printing press roller, laminating machine roller, film slitting roller. 4. New energy and electronics industry Applications: lithium battery electrode rolling roller, photovoltaic silicon wafer conveying roller, semiconductor product circular guide roller. 5. Textile and paper industry Application: Textile guide roller, drying roller, papermaking calendering roller. 6. Automotive and Metal Processing Application: Steel plate rolling roller, welding production line conveyor roller, spraying line guide roller. 7. Pharmaceuticals and Medical Devices Applications: pharmaceutical equipment conveyor rollers, medical film coating rollers, disinfection equipment rollers. The diversified design of stainless steel rollers, such as hollow rollers and jacket heating rollers, can meet the needs of different industries. When customizing, it is necessary to clarify the operating parameters (load, speed, temperature, etc.). |

Patented Technology · New Materials

to be the high end material and application expert in the mechanic industry

|

Contact Us

Address: No. 13, Longxiangge nine Street, Chaolang Village, Chashan Town, Dongguan City

TEL:+86-769 - 81218861

Email:dgosnai@163.com http://www.www.meilanc.cn 24-hour service phone: 4007-566-899

|

|

Copyright 2016 Dongguan OSNAI new materials co. LTD-All rights reserved For the record:Guangdong ICP for NO.17078892 |